Dubstar_04 - 40w Chinese Laser DSP Conversion

-

dubstar_04

- Posts: 35

- Joined: Sat Jan 19, 2013 9:24 am

- Contact:

Dubstar_04 - 40w Chinese Laser DSP Conversion

I would like to introduce myself, My name is Dan, I am in the UK and i have recently bought a K40 Chinese laser. The machine arrived well packaged and everything seems ok, however the mainboard is faulty.

I was prepared for this and i have ordered the 2012 DSP and will be using this forum to document the build and hopefully get help with the conversion.

First couple of question:

1. I would like to use a flowmeter to protect the laser from firing when the coolant isnt flowing. is there a particular model that other people have used?

2. Where can i get the software for the DSP (LaserCAD?) and the AutoCAD Plugin. I would like to give install it and learn it before the DSP arrives.

Thanks,

Dan

I was prepared for this and i have ordered the 2012 DSP and will be using this forum to document the build and hopefully get help with the conversion.

First couple of question:

1. I would like to use a flowmeter to protect the laser from firing when the coolant isnt flowing. is there a particular model that other people have used?

2. Where can i get the software for the DSP (LaserCAD?) and the AutoCAD Plugin. I would like to give install it and learn it before the DSP arrives.

Thanks,

Dan

-

dubstar_04

- Posts: 35

- Joined: Sat Jan 19, 2013 9:24 am

- Contact:

Started the conversion

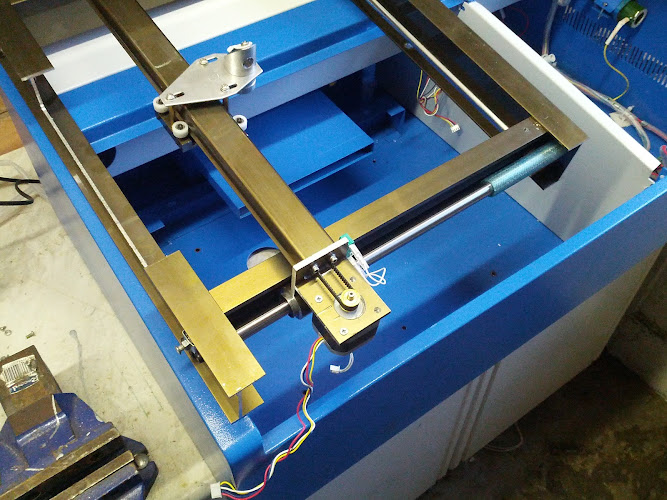

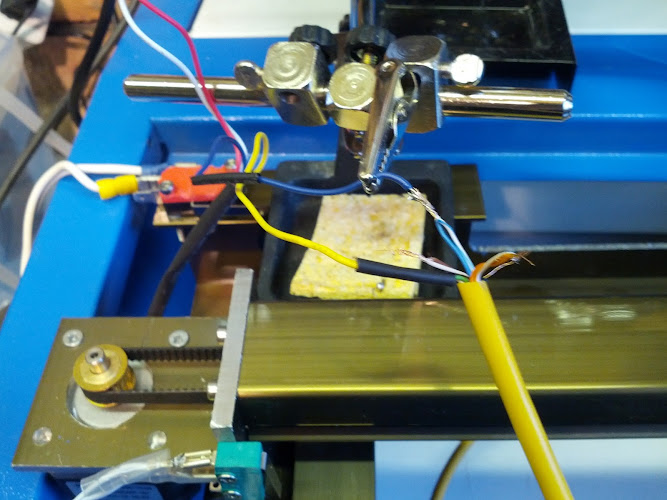

Stripped the machine down and removed the X - Y stage:

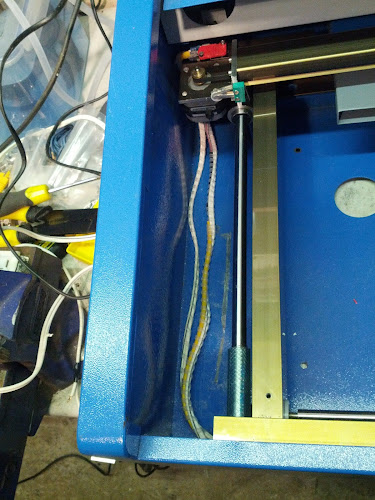

Removed all the electronics:

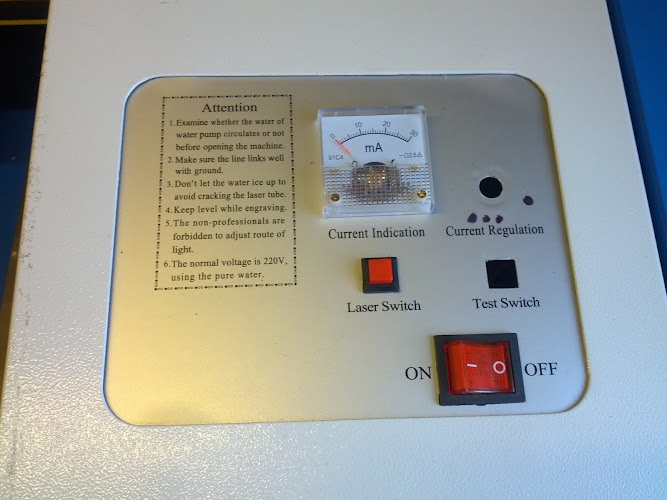

Removed some of the controls I don't want:

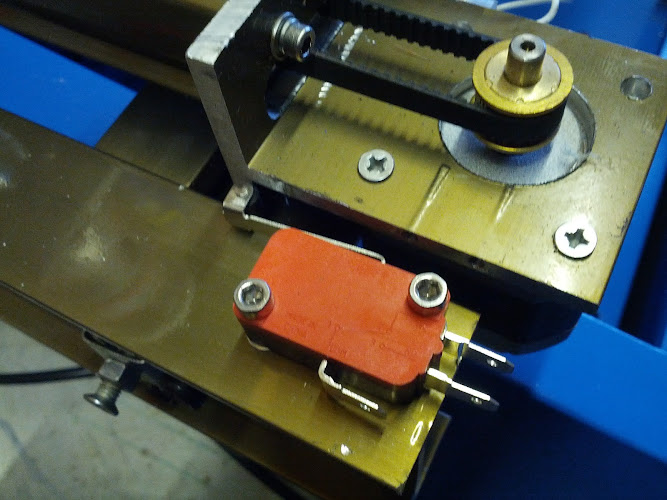

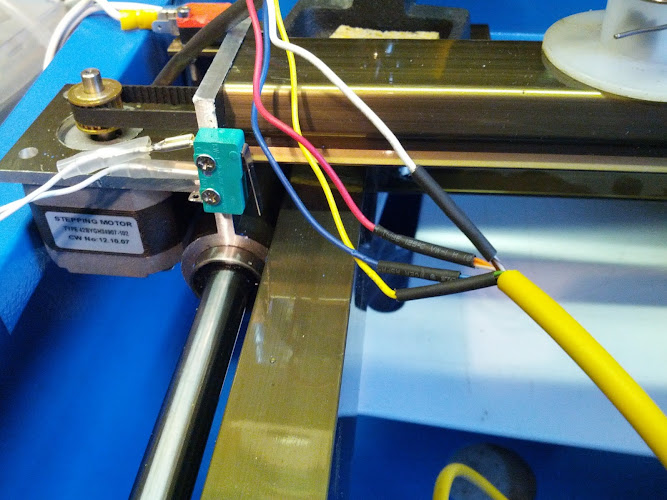

Added a mechanical endstop on the Y axis:

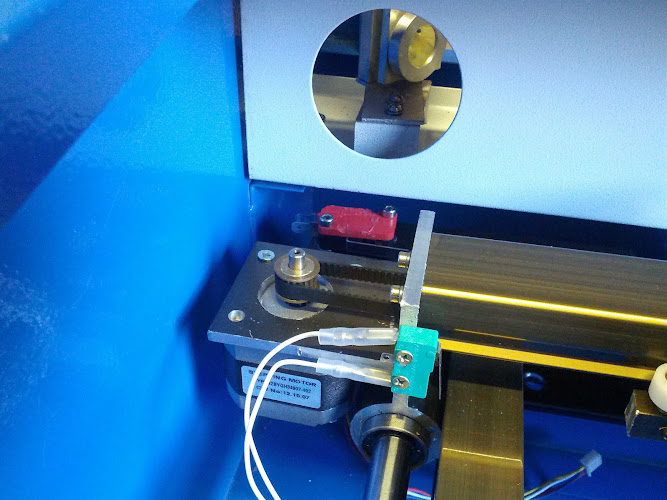

Added a lid safety switch:

More soon...

Removed all the electronics:

Removed some of the controls I don't want:

Added a mechanical endstop on the Y axis:

Added a lid safety switch:

More soon...

-

dubstar_04

- Posts: 35

- Joined: Sat Jan 19, 2013 9:24 am

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Small update:

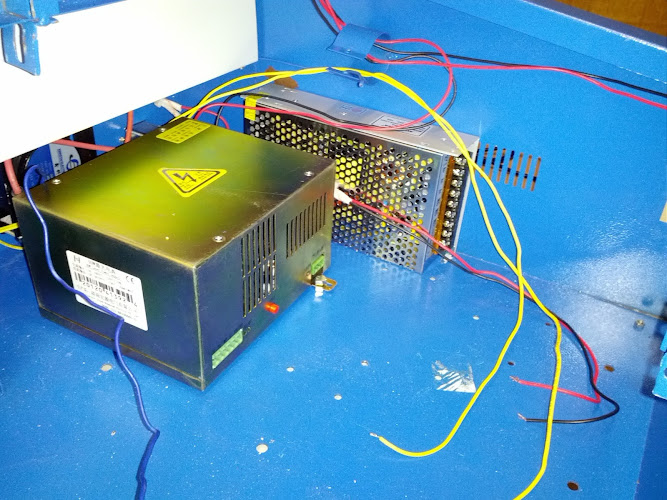

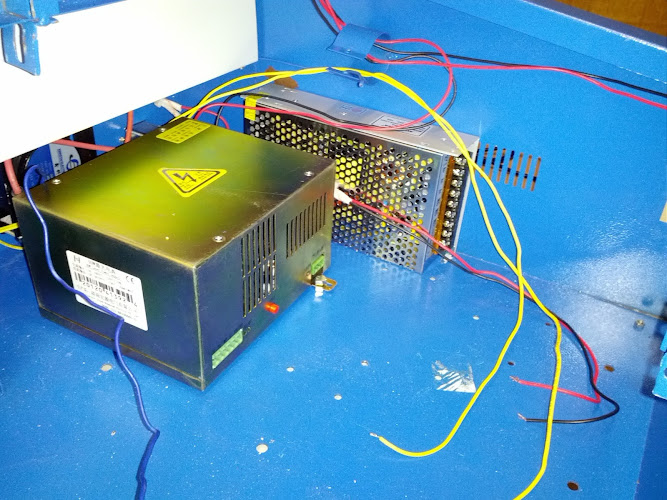

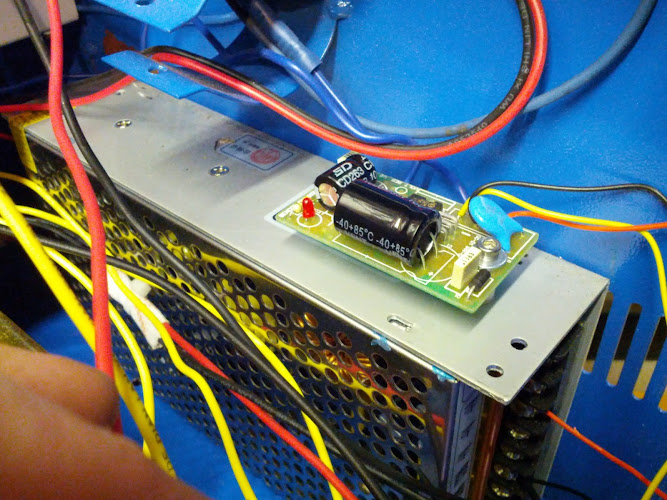

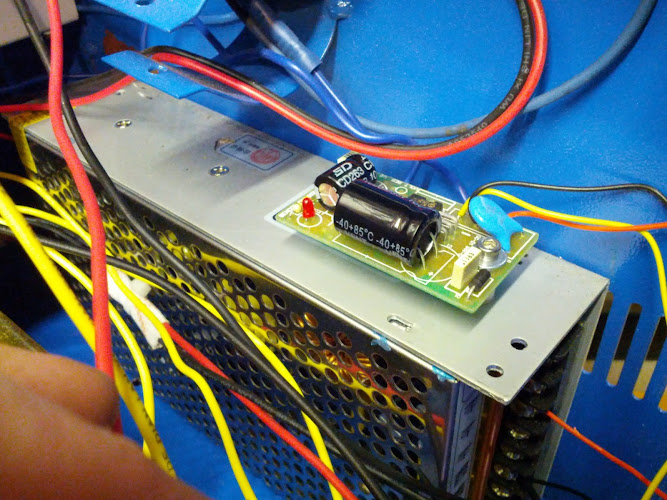

I have started to install the new 24v 10A Power supply and the Laser PSU. I have reused the existing Ammeter but rewired it using a consistant wiring colouring.

According to the tracking data the DSP and the rest of the shipment from Marco has landed in the UK now so it should be here tomorrow or Wednesday.

More soon...

I have started to install the new 24v 10A Power supply and the Laser PSU. I have reused the existing Ammeter but rewired it using a consistant wiring colouring.

According to the tracking data the DSP and the rest of the shipment from Marco has landed in the UK now so it should be here tomorrow or Wednesday.

More soon...

-

dubstar_04

- Posts: 35

- Joined: Sat Jan 19, 2013 9:24 am

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

The goods have arrived in the UK. I now have to pay import duty and VAT on the items!!

-

dubstar_04

- Posts: 35

- Joined: Sat Jan 19, 2013 9:24 am

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

I was contacted by UK customs and excise and required to pay duty and VAT on my order. That's all sorted now and the DSP is on its way.

I have spent more time working on the machine, the tasks i have completed are summerised below:

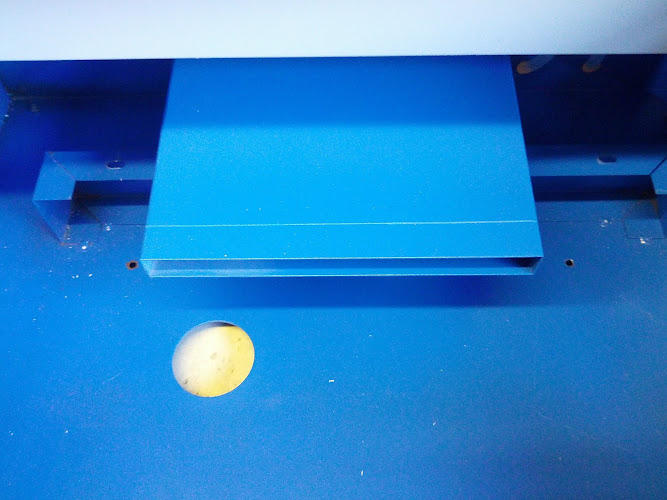

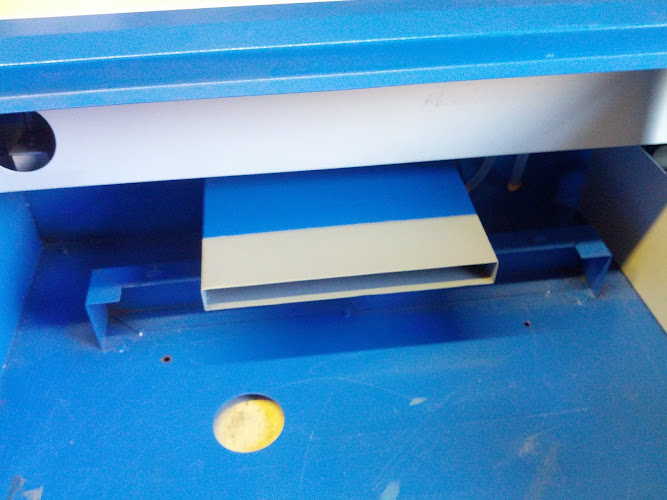

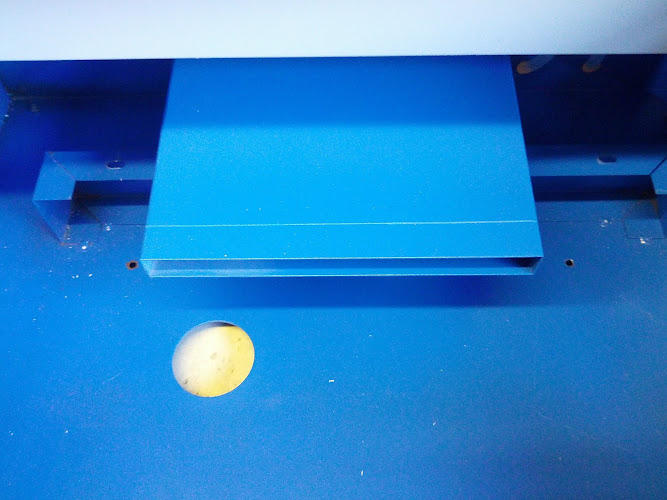

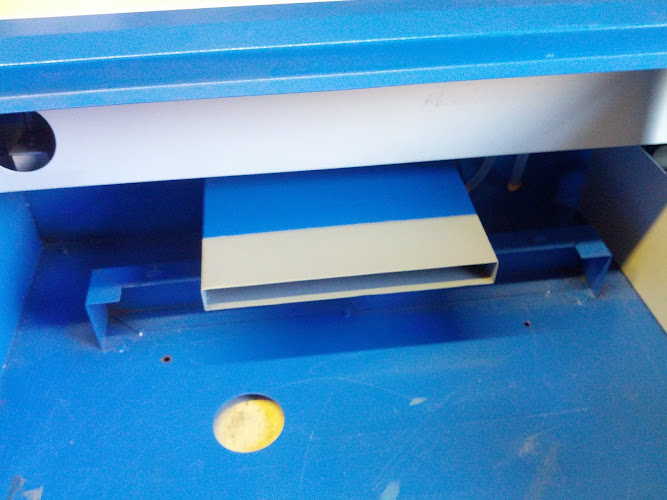

Trim the exhaust tunnel:

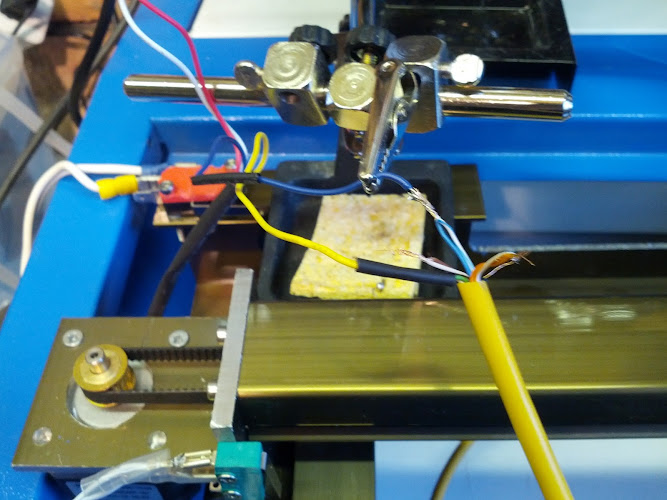

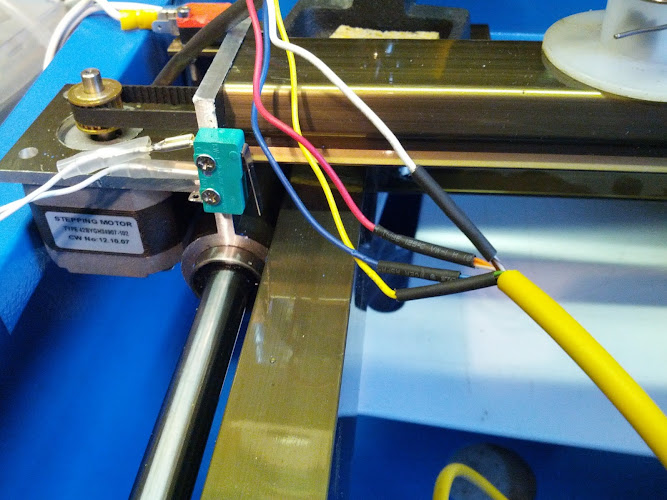

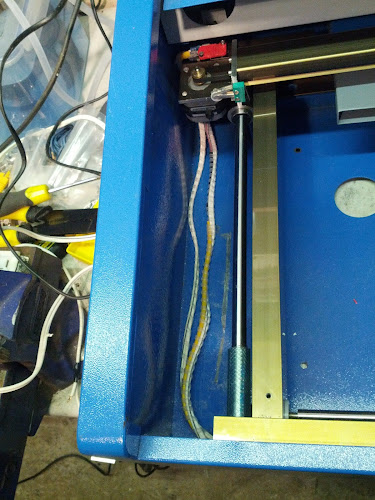

Replace the ribbon cable to the stepper motor:

Added internal lighting:

12v Regulator for lighting:

Installed stepper drivers:

Wired in the lid switch:

Replaced the orange lid with a clear lid:

Replaced all the nuts with nylon lock nuts:

I am hoping the DSP arrives in a couple of days. if it does i should have the machine running again early next week.

More soon...

I have spent more time working on the machine, the tasks i have completed are summerised below:

Trim the exhaust tunnel:

Replace the ribbon cable to the stepper motor:

Added internal lighting:

12v Regulator for lighting:

Installed stepper drivers:

Wired in the lid switch:

Replaced the orange lid with a clear lid:

Replaced all the nuts with nylon lock nuts:

I am hoping the DSP arrives in a couple of days. if it does i should have the machine running again early next week.

More soon...

-

dubstar_04

- Posts: 35

- Joined: Sat Jan 19, 2013 9:24 am

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

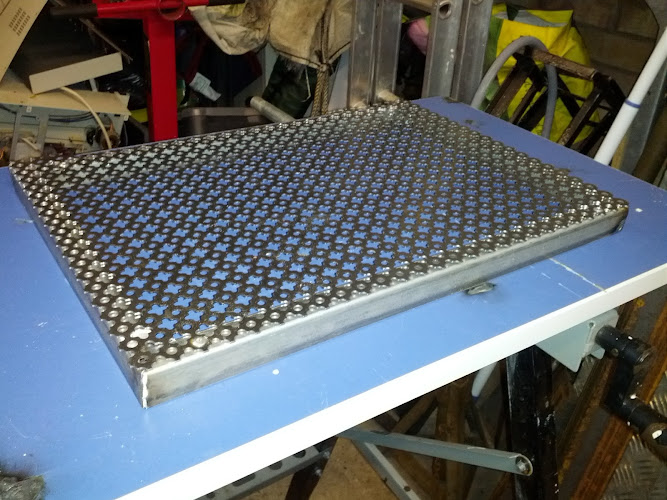

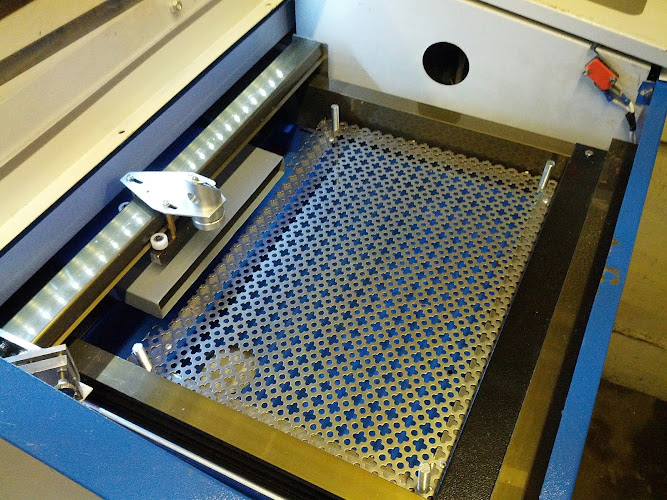

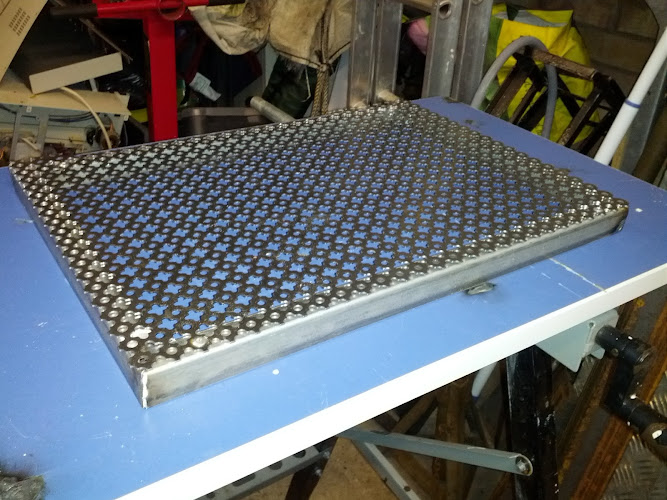

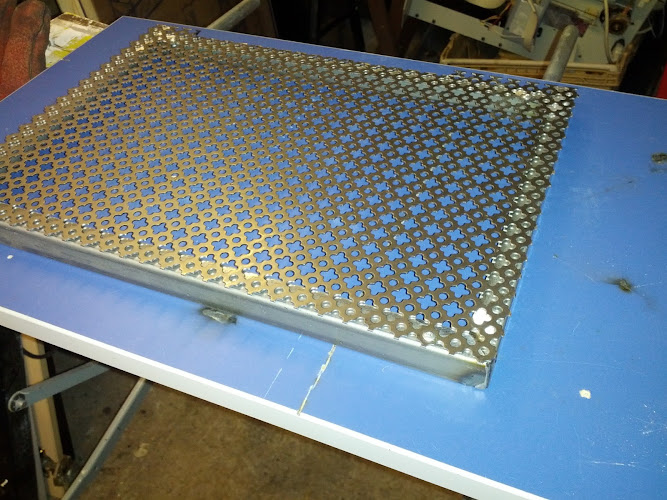

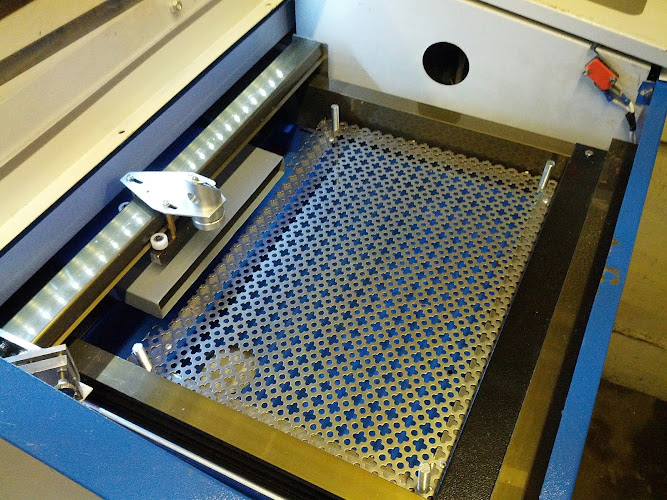

Managed to spend a little more time on the laser today, this time i was focused on starting an adjustable bed.

I made a steel frame from rolled steel angle and cut the steel sheet to fit:

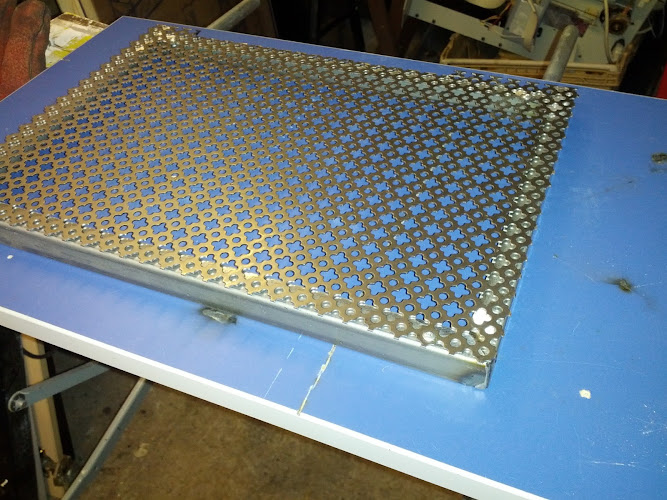

Testing the fit:

For the adjustment I have drilled holes through the bed and bed frame then welded 8mm nuts to the underside of the frame. I have used 8mm threaded from through the nuts to support the bed:

I intend to complete the bed by adding a base and either a stepper motor or a dc motor to control the height.

more soon...

I made a steel frame from rolled steel angle and cut the steel sheet to fit:

Testing the fit:

For the adjustment I have drilled holes through the bed and bed frame then welded 8mm nuts to the underside of the frame. I have used 8mm threaded from through the nuts to support the bed:

I intend to complete the bed by adding a base and either a stepper motor or a dc motor to control the height.

more soon...

-

dubstar_04

- Posts: 35

- Joined: Sat Jan 19, 2013 9:24 am

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Quick update:

DSP finally arrived after a tour of the uk post offices.

Its all wired up and homes correctly but i can't do anything with it as i dont have any software.

DSP finally arrived after a tour of the uk post offices.

Its all wired up and homes correctly but i can't do anything with it as i dont have any software.

-

Tech_Marco

- Posts: 4658

- Joined: Mon Jun 15, 2009 3:00 pm

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Software links sent. Check your email

Have fun!

Marco

Have fun!

Marco

-

dubstar_04

- Posts: 35

- Joined: Sat Jan 19, 2013 9:24 am

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Nothing on my email yet. Can you resend?Tech_Marco wrote:Software links sent. Check your email

Have fun!

Marco

-

Tech_Marco

- Posts: 4658

- Joined: Mon Jun 15, 2009 3:00 pm

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Acutally by "PM", not email

Check again

Marco

Check again

Marco

-

dubstar_04

- Posts: 35

- Joined: Sat Jan 19, 2013 9:24 am

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

I have them now thanks!!Tech_Marco wrote:Acutally by "PM", not email

Check again

Marco

I have a few questions about the DSP setup:

Question 1:

I have tried loading the updated software files to the machine, I select them from udisk and press enter on the keypad and it says error for V6, v7 and v8.

Which file do i need to upgrade to? How do i upgrade?

Question 2:

The laser works and cuts the work piece but it wont turn off afterwards, how can i solve this?

Question 3:

If i set the origin and press box or start the machine moves to 0, 0 and cuts from there. How do i position the machine to cut where i want?

Thanks,

Dan

-

Tech_Marco

- Posts: 4658

- Joined: Mon Jun 15, 2009 3:00 pm

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Question 1:I have tried loading the updated software files to the machine, I select them from udisk and press enter on the keypad and it says error for V6, v7 and v8. Which file do i need to upgrade to? How do i upgrade?

Ans: Look at the version of yours by using the LCD control. Scroll down to the last one and check the version. It will show one of those 6,7, or 8. Use a USB memory stick 2GB to 8Gb and plug it into the USB connector on the DSP controller.

But, you don't need to do it as you're the latest one.

Question 2:The laser works and cuts the work piece but it wont turn off afterwards, how can i solve this?

Ans: Check "TH" or "TL" connection. You may want to use "TL" to instead of "TH" for firing control

Question 3:

If i set the origin and press box or start the machine moves to 0, 0 and cuts from there. How do i position the machine to cut where i want?

Ans: Use LCD control panel to change the Origin setting. Currently you're using "Machine Origin". But you may want to use the other two modes; Software or

Ans: Look at the version of yours by using the LCD control. Scroll down to the last one and check the version. It will show one of those 6,7, or 8. Use a USB memory stick 2GB to 8Gb and plug it into the USB connector on the DSP controller.

But, you don't need to do it as you're the latest one.

Question 2:The laser works and cuts the work piece but it wont turn off afterwards, how can i solve this?

Ans: Check "TH" or "TL" connection. You may want to use "TL" to instead of "TH" for firing control

Question 3:

If i set the origin and press box or start the machine moves to 0, 0 and cuts from there. How do i position the machine to cut where i want?

Ans: Use LCD control panel to change the Origin setting. Currently you're using "Machine Origin". But you may want to use the other two modes; Software or

-

dubstar_04

- Posts: 35

- Joined: Sat Jan 19, 2013 9:24 am

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Thanks Marco,

That has solved my problems.

I will post some pictures when i have something worth showing.

Thanks,

Dan

That has solved my problems.

I will post some pictures when i have something worth showing.

Thanks,

Dan

-

dubstar_04

- Posts: 35

- Joined: Sat Jan 19, 2013 9:24 am

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Update:

The DSP is installed and working great. I am going to be making my sisters wedding invites using the machine.

Here is a video of the first cuts it made: http://www.youtube.com/watch?v=iiXLPGnvmxE

I have also tried cutting clear acrylic, which worked ok. It did seem to crack the material in places.

Cutting coloured acrylic works brilliantly, beautiful cuts at 7.5mm/s and 90% power.

I really wanted to be able to cut wood using the machine but as yet i can't cut any type of wood without it burning.

Anyone else had any luck?

EDIT: After a google search i have ordered some 3mm birch ply as this seems to be the wood of choice for laser cutting.

The DSP is installed and working great. I am going to be making my sisters wedding invites using the machine.

Here is a video of the first cuts it made: http://www.youtube.com/watch?v=iiXLPGnvmxE

I have also tried cutting clear acrylic, which worked ok. It did seem to crack the material in places.

Cutting coloured acrylic works brilliantly, beautiful cuts at 7.5mm/s and 90% power.

I really wanted to be able to cut wood using the machine but as yet i can't cut any type of wood without it burning.

Anyone else had any luck?

EDIT: After a google search i have ordered some 3mm birch ply as this seems to be the wood of choice for laser cutting.

-

1n2

- Posts: 113

- Joined: Tue Jan 29, 2013 10:46 am

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Hi Dubstardubstar_04 wrote:

I really wanted to be able to cut wood using the machine but as yet i can't cut any type of wood without it burning.

Anyone else had any luck?

EDIT: After a google search i have ordered some 3mm birch ply as this seems to be the wood of choice for laser cutting.

Today I have spent 5 hours experimenting with settings and materials.....should have been working but hey ho.

I cut 3mm birch ply beautifully just a little browning of the edge.

After much testing I used speed 13 and power 41% perfect cut no burning!

Just out of curiosity which way up have you got your lens ? I cut and engrave MUCH cleaner with the curve down.

Hope this helps

John

Who is online

Users browsing this forum: No registered users and 2 guests