Dubstar_04 - 40w Chinese Laser DSP Conversion

-

Things

- Posts: 96

- Joined: Sat Mar 17, 2012 7:08 pm

- Location: Cairns, Australia

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Engraving puts much larger inertial forces on the machine than plain vector cutting, I'd be pretty certain it's a mechanical issue with your machine rather than the DSP.

Try importing a small image, engrave it, then engrave it again. If the 2nd time it doesn't completely overlap perfectly, you can almost be sure it's a mechanical issue.

Try importing a small image, engrave it, then engrave it again. If the 2nd time it doesn't completely overlap perfectly, you can almost be sure it's a mechanical issue.

-

1n2

- Posts: 113

- Joined: Tue Jan 29, 2013 10:46 am

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Hi Dan

Indeed you're getting somewhere.

Now I read about a setting/choice that if incorrect will or can cause miss alignment issues....All I have to do is find where I read it

Found it ...look at the "pulse edge" setting. The manual says

"[Pulse Edge]: Trigger edge when motor is rotated by motor driver. If the pulse edge setting is not correct, may lead to cutting dislocation."

hope this helps

John

Indeed you're getting somewhere.

Now I read about a setting/choice that if incorrect will or can cause miss alignment issues....All I have to do is find where I read it

Found it ...look at the "pulse edge" setting. The manual says

"[Pulse Edge]: Trigger edge when motor is rotated by motor driver. If the pulse edge setting is not correct, may lead to cutting dislocation."

hope this helps

John

-

waltfl

- Posts: 674

- Joined: Thu Sep 08, 2011 5:29 am

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Hi there

you should select GAP optimizing in the download to the machine menue or select cut after engrave.

the power with PPI is completly different as regular cut the laser max settings in the manufacturer setting do not prevent

from over powering most machines need only about 45 to 55 % to go to 18mA allready.

greetings

waltfl

you should select GAP optimizing in the download to the machine menue or select cut after engrave.

the power with PPI is completly different as regular cut the laser max settings in the manufacturer setting do not prevent

from over powering most machines need only about 45 to 55 % to go to 18mA allready.

greetings

waltfl

dubstar_04 wrote:Hi john1n2 wrote: Hi Dan

Regarding power if the lens is not dirty then

My guess would be either your alignment is bad or the work piece is out of focus I cut 6mm acrylic easily with 50% power setting at a speed of 3 (agreed this is with air assist.)

I posted some boxes I had made with 3mm birch ply. these were cut at a speed of 13 and power set to 41.

18Mamps seems to be the max (100%)for a 40 watt tube according to the guff I have read. (that is if I understood what I read correctly)

and further it seems that 100% in the Lasercad software does not equal 100% (18Ma) on the laser 18Ma seems to be achieved way before 100%

now the miss-alignment.Is it happening with ALL your drawings?

I hope I am not teaching grandma to suck eggs...this is how I would go about it (and did so to find two faults.....1 caused by me, loose connection, and 1was a bad microswitch)

By a process of elimination we should be able to sort it.

If its happening consistently with everything I would say to look at settings.

If it happens randomly ie in a different place each time with the same drawings I would look for a loose connection.

If its happening with just that drawing (or all drawings from the same source) I would look to the drawing.

My method would be make a very basic drawing (using Lasercad thereby eliminating corel draw from the equation) that engraves a shape then cuts the engraving out. By keeping it simple to start we should be able add tests one thing at a time.(sorry if this is obvious but sometimes when ya too close to the elephant all you see is grey)

John

PS did you draw the kindle rest or get the file elsewhere?..

i found kindle stand on thingiverse, it was meant to be a phone holder, but i scaled it accordingly.

I am making a little progress.

Power:

It seems to be a problem with using the PPI feature. i.e If PPI is selected the machine cannot fully cut 3mm Birch ply with a power setting < 75%

Without PPI, 10mm/s and 25% power gets a clean cut.

Alignment:

It seems that the problem is caused by engraving.

if i cut an object that has no engraving it works fine,however ifi cut the same object with engraving it all becomes missaligned.

I can reproduce this consistantly.

I am really dissapointed with this issue as i bought a DSP specifically for this task rather than a cheaper alternative from a Laos board or chris's circuits, so i hope to get it resolved.

i will upload some photos of the attached file being cut to show the missalignment on a number of attempts.

thanks,

Dan

-

dubstar_04

- Posts: 35

- Joined: Sat Jan 19, 2013 9:24 am

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Thanks guys,1n2 wrote:Hi Dan

Indeed you're getting somewhere.

Now I read about a setting/choice that if incorrect will or can cause miss alignment issues....All I have to do is find where I read it

Found it ...look at the "pulse edge" setting. The manual says

"[Pulse Edge]: Trigger edge when motor is rotated by motor driver. If the pulse edge setting is not correct, may lead to cutting dislocation."

hope this helps

John

I will try these things later. Maybe i need to slow the engraving process down and have a look at the pulse edge setting. I am currently engraving at 100 mm/s or 150 mm/s maybe i should take it down to 50 mm/s and work up once i know its a mechanical issue.

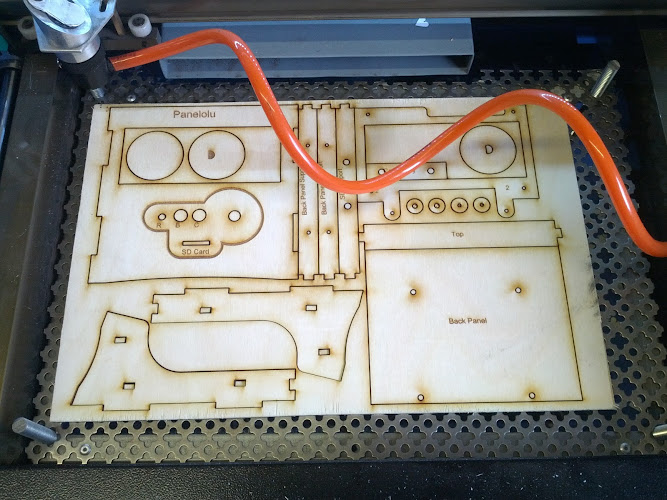

Here are a few images of the finished piece:

The first two images show the circle to the right of the "R B C" is completely mis-shaped and all the engraving is offset to the left.

-

dubstar_04

- Posts: 35

- Joined: Sat Jan 19, 2013 9:24 am

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Hi Waltfl,waltfl wrote:Hi there

you should select GAP optimizing in the download to the machine menue or select cut after engrave.

the power with PPI is completly different as regular cut the laser max settings in the manufacturer setting do not prevent

from over powering most machines need only about 45 to 55 % to go to 18mA allready.

greetings

waltfl

Whats does the GAP optimising do?

Would 'cut after engrave' affect the mis-alignment?

Thanks,

Dan

-

waltfl

- Posts: 674

- Joined: Thu Sep 08, 2011 5:29 am

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

hi Dan

yes the GAP optimizing lines the cutting up and the cut after engrave holds the position better then engraving and cutting seperate.

greetings

waltfl

yes the GAP optimizing lines the cutting up and the cut after engrave holds the position better then engraving and cutting seperate.

greetings

waltfl

dubstar_04 wrote:Hi Waltfl,waltfl wrote:Hi there

you should select GAP optimizing in the download to the machine menue or select cut after engrave.

the power with PPI is completly different as regular cut the laser max settings in the manufacturer setting do not prevent

from over powering most machines need only about 45 to 55 % to go to 18mA allready.

greetings

waltfl

Whats does the GAP optimising do?

Would 'cut after engrave' affect the mis-alignment?

Thanks,

Dan

-

1n2

- Posts: 113

- Joined: Tue Jan 29, 2013 10:46 am

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Hi Dan

it looks like these drawings are from the same source (cool as they are).

does this same effect happen on your own drawings?

Also you seem to have a lot of burning (especially with your air assist ) but that might be the slow speeds ya using to engrave.

I engrave birch ply at around 250 speed and 22 power

John

it looks like these drawings are from the same source (cool as they are).

does this same effect happen on your own drawings?

Also you seem to have a lot of burning (especially with your air assist ) but that might be the slow speeds ya using to engrave.

I engrave birch ply at around 250 speed and 22 power

John

-

dubstar_04

- Posts: 35

- Joined: Sat Jan 19, 2013 9:24 am

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

These are my drawings. I have been using AutoCAD to draw the designs and there is a LaserCAD toolbar that transfers the design.1n2 wrote:Hi Dan

it looks like these drawings are from the same source (cool as they are).

does this same effect happen on your own drawings?

Also you seem to have a lot of burning (especially with your air assist ) but that might be the slow speeds ya using to engrave.

I engrave birch ply at around 250 speed and 22 power

John

There is a lot of burning on some of the photos, i am still messing with settings to find what works.

i am currently engraving at 50mm/s to see if that keeps the cuts and engraving aligned.

It seems to be working so i might just need to tighten the belts.

waltfl,

The cut after engrave options asks for an engraving speed and power, but i don't want to engrave those parts of the design, just cut them. Does it cut and engrave?

-

dubstar_04

- Posts: 35

- Joined: Sat Jan 19, 2013 9:24 am

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

I tried engraving at 50mm/s and the problem is alot worse.Things wrote:Engraving puts much larger inertial forces on the machine than plain vector cutting, I'd be pretty certain it's a mechanical issue with your machine rather than the DSP.

Try importing a small image, engrave it, then engrave it again. If the 2nd time it doesn't completely overlap perfectly, you can almost be sure it's a mechanical issue.

First attempt 50mm/s: holes are cut in the wrong place.

Attempt 2: Even worse and text mis-aligned

Attempt 3: Exactly the same result at attempt 2.

i really dont know whats going on!!

Any ideas?

-

waltfl

- Posts: 674

- Joined: Thu Sep 08, 2011 5:29 am

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Hi dan

everytime you want part of a design to do you one thing you need to selct them and give them a different color and then put in at the layer what you wana do for sample you select the part then give it red ( from the bottom color scale) then select ether cutt or engrave or cut after engrave then put the speed and the power in.

the cut and engrave selection engraves first the part you have selected then cut this out. you also can select from the tools menue select create a image outlin give it a different color and select cut and this just cut the outline.

the best way to help you is if you post the file that i can see what is going on

greetings

walt

everytime you want part of a design to do you one thing you need to selct them and give them a different color and then put in at the layer what you wana do for sample you select the part then give it red ( from the bottom color scale) then select ether cutt or engrave or cut after engrave then put the speed and the power in.

the cut and engrave selection engraves first the part you have selected then cut this out. you also can select from the tools menue select create a image outlin give it a different color and select cut and this just cut the outline.

the best way to help you is if you post the file that i can see what is going on

greetings

walt

dubstar_04 wrote:These are my drawings. I have been using AutoCAD to draw the designs and there is a LaserCAD toolbar that transfers the design.1n2 wrote:Hi Dan

it looks like these drawings are from the same source (cool as they are).

does this same effect happen on your own drawings?

Also you seem to have a lot of burning (especially with your air assist ) but that might be the slow speeds ya using to engrave.

I engrave birch ply at around 250 speed and 22 power

John

There is a lot of burning on some of the photos, i am still messing with settings to find what works.

i am currently engraving at 50mm/s to see if that keeps the cuts and engraving aligned.

It seems to be working so i might just need to tighten the belts.

waltfl,

The cut after engrave options asks for an engraving speed and power, but i don't want to engrave those parts of the design, just cut them. Does it cut and engrave?

-

dubstar_04

- Posts: 35

- Joined: Sat Jan 19, 2013 9:24 am

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Hi Waltfl,

I understand how to set up the jobs in LaserCAD, however, Cut after engrave isn't the correct operation for what i am trying to achieve as the parts are either cut or engraved, not both.

There is a sample file a few posts back if you could have a look at that.

EDIT: I have attached the file to the post.

I'm really stuck to work out what is happening. I have emailed Marco so hopefully he can offer some advice.

Thanks,

Dan

I understand how to set up the jobs in LaserCAD, however, Cut after engrave isn't the correct operation for what i am trying to achieve as the parts are either cut or engraved, not both.

There is a sample file a few posts back if you could have a look at that.

EDIT: I have attached the file to the post.

I'm really stuck to work out what is happening. I have emailed Marco so hopefully he can offer some advice.

Thanks,

Dan

waltfl wrote:Hi dan

everytime you want part of a design to do you one thing you need to selct them and give them a different color and then put in at the layer what you wana do for sample you select the part then give it red ( from the bottom color scale) then select ether cutt or engrave or cut after engrave then put the speed and the power in.

the cut and engrave selection engraves first the part you have selected then cut this out. you also can select from the tools menue select create a image outlin give it a different color and select cut and this just cut the outline.

the best way to help you is if you post the file that i can see what is going on

greetings

walt

dubstar_04 wrote:These are my drawings. I have been using AutoCAD to draw the designs and there is a LaserCAD toolbar that transfers the design.1n2 wrote:Hi Dan

it looks like these drawings are from the same source (cool as they are).

does this same effect happen on your own drawings?

Also you seem to have a lot of burning (especially with your air assist ) but that might be the slow speeds ya using to engrave.

I engrave birch ply at around 250 speed and 22 power

John

There is a lot of burning on some of the photos, i am still messing with settings to find what works.

i am currently engraving at 50mm/s to see if that keeps the cuts and engraving aligned.

It seems to be working so i might just need to tighten the belts.

waltfl,

The cut after engrave options asks for an engraving speed and power, but i don't want to engrave those parts of the design, just cut them. Does it cut and engrave?

- Attachments

-

- PANELOLUCASE-FINAL.pwj5

- (201.48 KiB) Downloaded 214 times

Last edited by dubstar_04 on Mon Mar 18, 2013 9:38 am, edited 1 time in total.

-

dubstar_04

- Posts: 35

- Joined: Sat Jan 19, 2013 9:24 am

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

How do you tighten the X-Belt on these machines?

Is it possible that the pulley could be slipping?

If i could remove any chance of the problem being a mechanical one i can move on to look at other things.

Is it possible that the pulley could be slipping?

If i could remove any chance of the problem being a mechanical one i can move on to look at other things.

-

1n2

- Posts: 113

- Joined: Tue Jan 29, 2013 10:46 am

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Hi Dandubstar_04 wrote:How do you tighten the X-Belt on these machines?

Is it possible that the pulley could be slipping?

If i could remove any chance of the problem being a mechanical one i can move on to look at other things.

I would think it doubtful if its a belt slipping especially at the low speeds you tried also a slipping belt would give random results (or at least a worst effect than you are getting ie slipping at each end of the axis) and a belt with teeth missing would surely cause every cut to step out of align where X meets Y ?

John

-

Tech_Marco

- Posts: 4652

- Joined: Mon Jun 15, 2009 3:00 pm

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Dan, what is setting of pulse setting on your DSP, Falling edge or Rising edge?

If you have Rising edge, change it to "Falling edge", one by one X & Y see if any improvement

Marco

If you have Rising edge, change it to "Falling edge", one by one X & Y see if any improvement

Marco

-

dubstar_04

- Posts: 35

- Joined: Sat Jan 19, 2013 9:24 am

- Contact:

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Hi Marco,

I am using the falling edge. Is it worth trying rising edge?

Thanks,

Dan

I am using the falling edge. Is it worth trying rising edge?

Thanks,

Dan

Tech_Marco wrote:Dan, what is setting of pulse setting on your DSP, Falling edge or Rising edge?

If you have Rising edge, change it to "Falling edge", one by one X & Y see if any improvement

Marco

Who is online

Users browsing this forum: No registered users and 6 guests