Page 3 of 6

Re: Rookie at Laser, NEED stupid questions answered

Posted: Tue Sep 24, 2013 3:13 am

by rushmore1305

ok so i have been out of town for a while but now im back to my laser.

so i was thinking about the air assist, and i picked up the Harbor Freight airbrush compressor, and its very quite, i am pleased.

and also found this airbrush kit on sale for 4$ that had this little hose attachment, i figured it would be perfect.

i guess i will let the pictures do the talking.

i used the existing nozzle that Light Object provided and threaded it

Re: Rookie at Laser, NEED stupid questions answered

Posted: Sat Sep 28, 2013 11:58 am

by rushmore1305

Hey guys, sorry for tons of pictures in this thread, but i am a rookie in the laser world, so i figured if i was on the fence of getting one of these i would like to see as much visual material you could possibly have

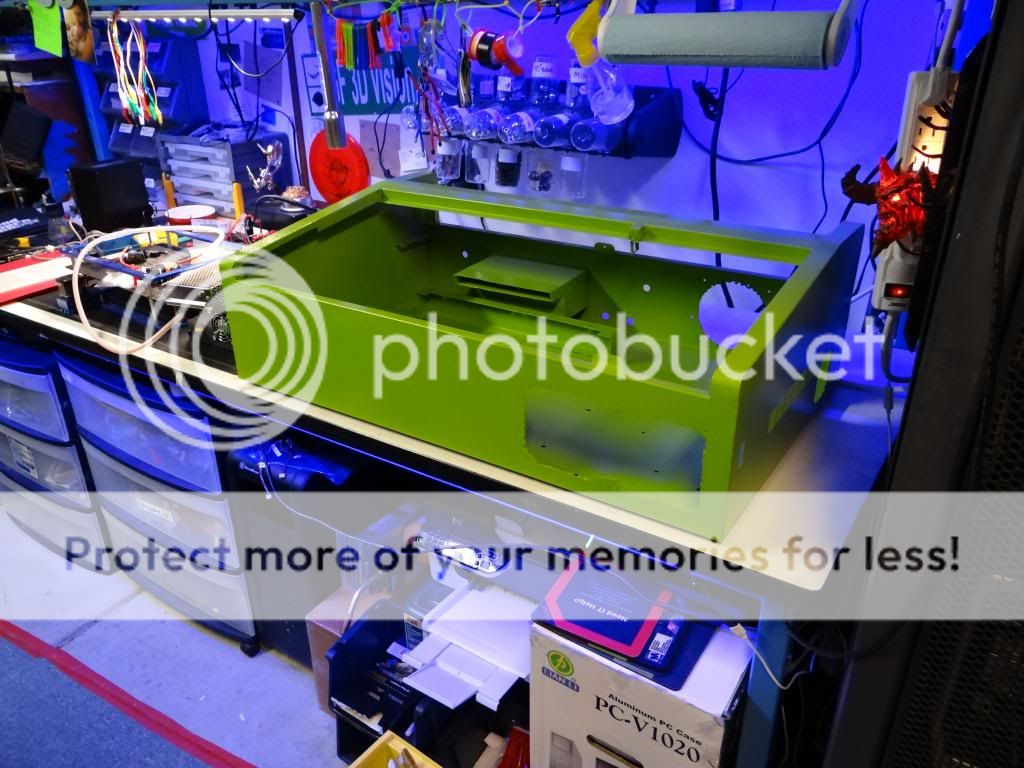

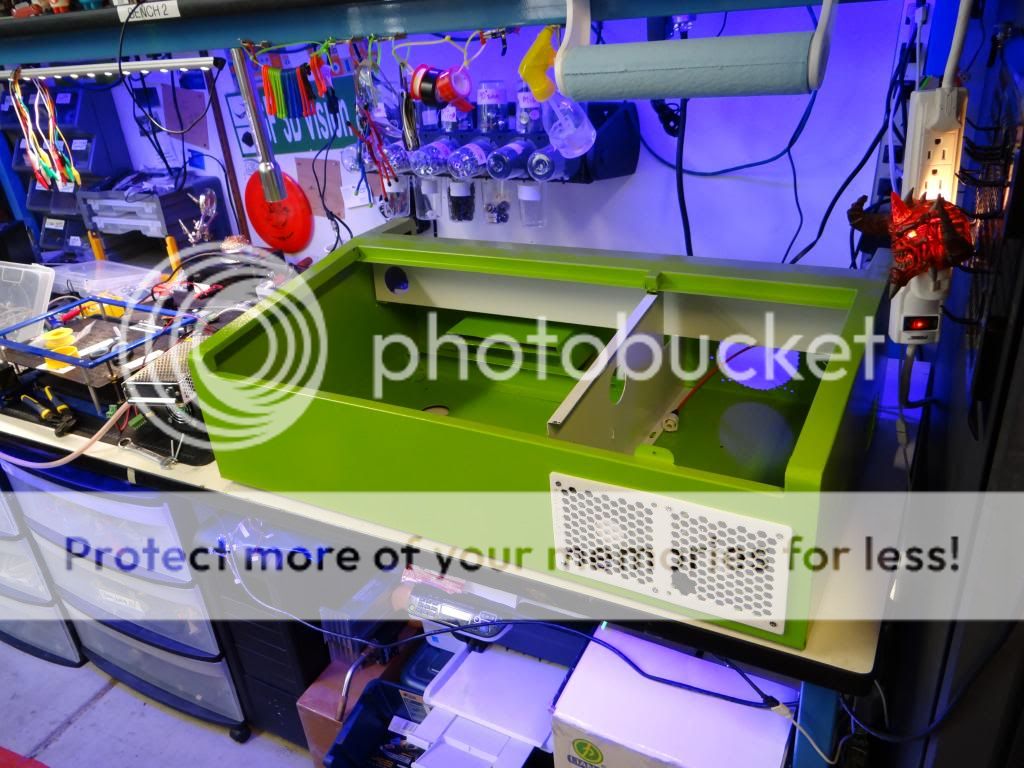

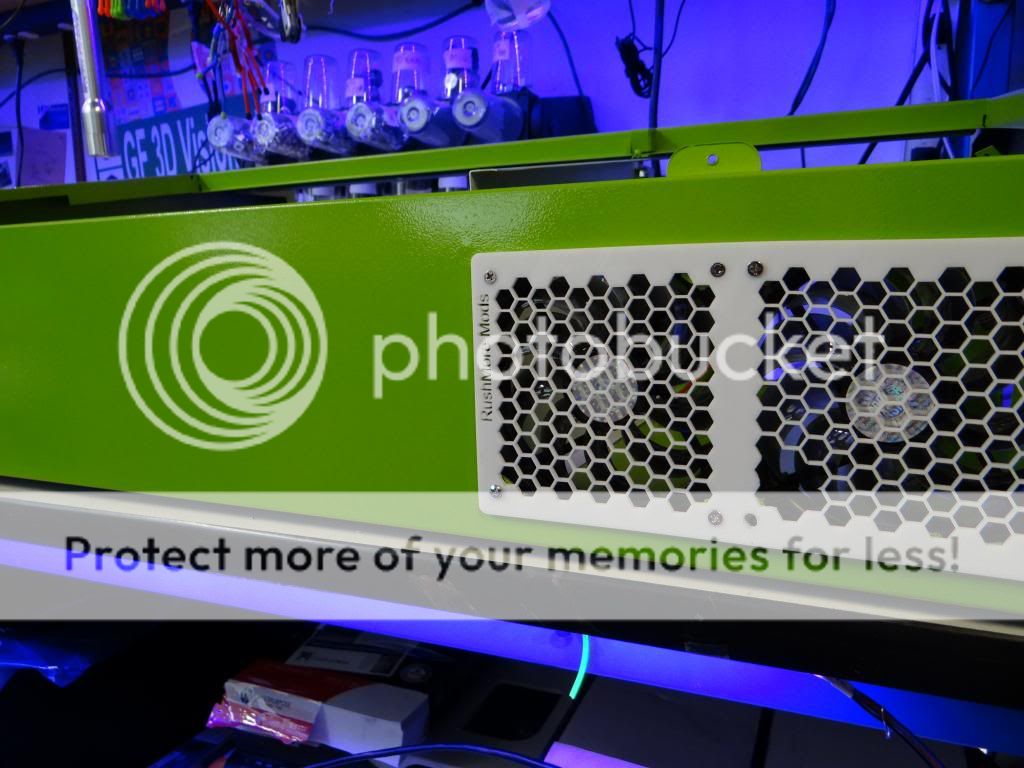

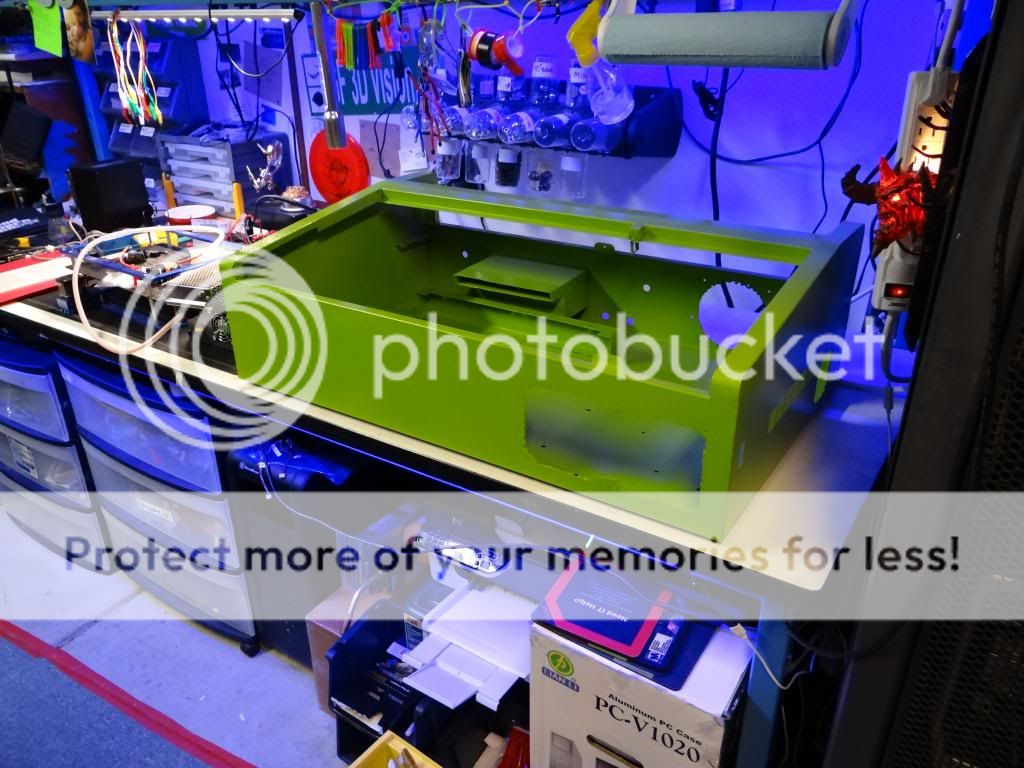

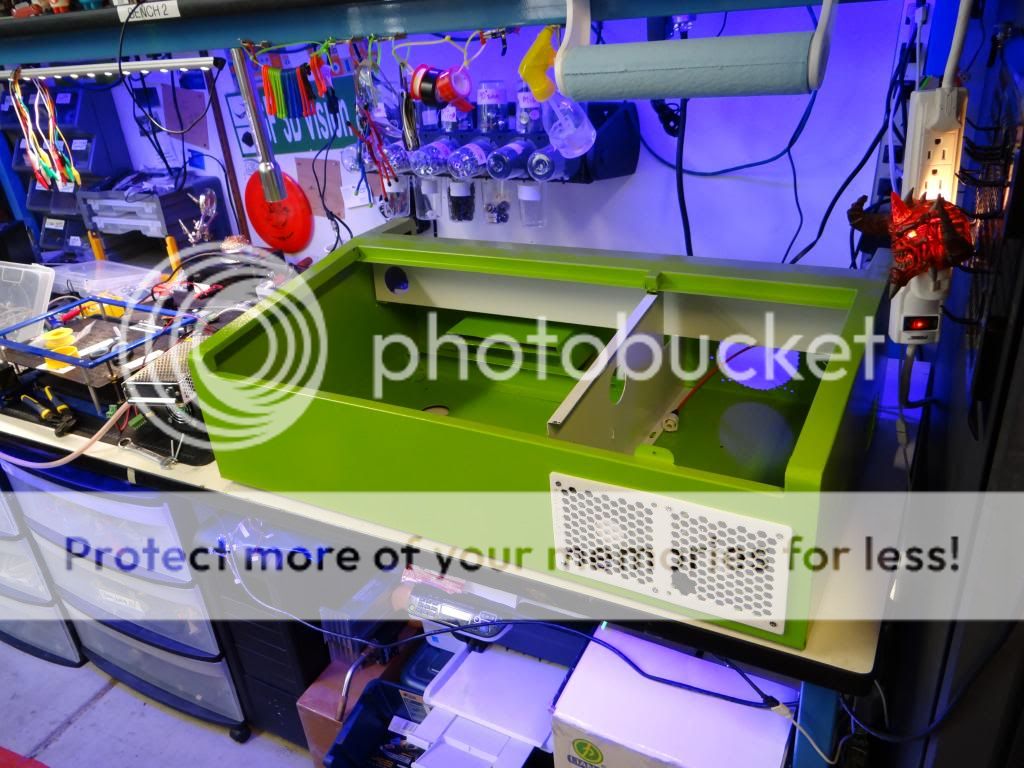

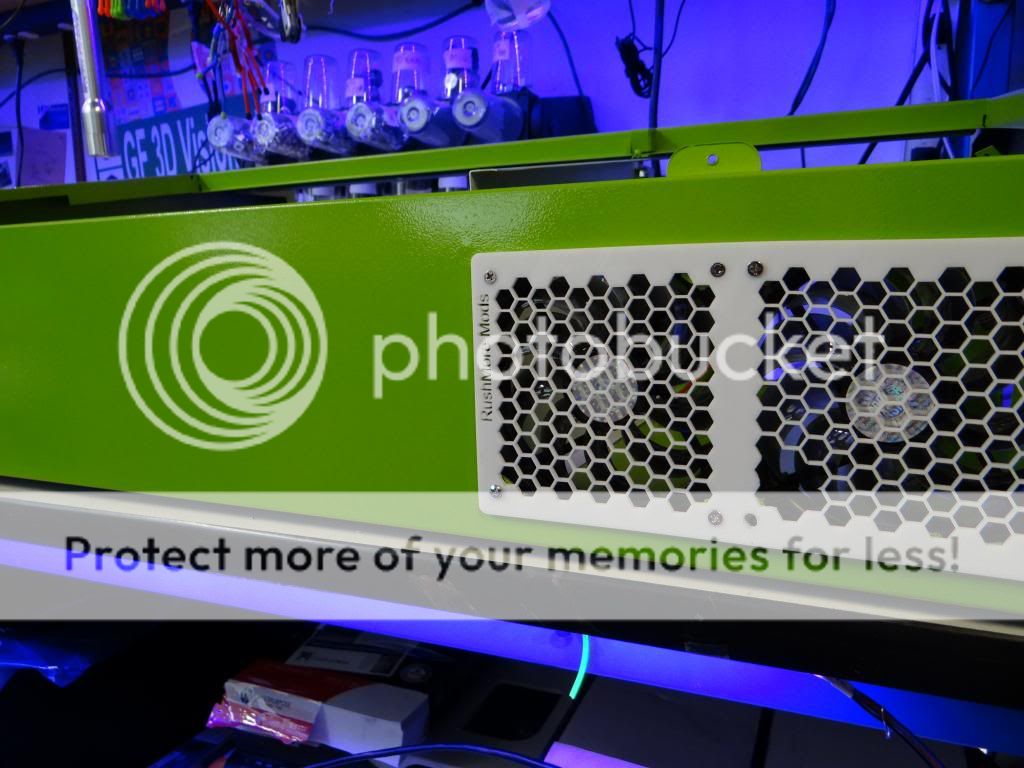

and me coming from the high computer world where we cool everything to the max and make everything unique i figured i might as well do that to mine, so this is what has become of my laser, over the next few days this machine will be 100% complete, with a Radiator Water Cooling system, Air assisted airbrush pump, and the Z motorized bed, also had some of those dip switches laying around so i am doing a little 6000k White LEDs that will light up the work surface and the control area once each door for that area opens up,

i guess i have so many pictures i don't really need to explain much more to you guys.

please don't mind the white grill being destroyed, i am so pissed at myself because my hand slipped and i snapped that, but i will just another one once my laser is up and running and it will be replaced.

so instead of the CAT 5 cable, i had some left over RGB cable from my RGB strip job that i did in my babies room, which i will show you some really cool pictures once this project is wrapped up, but its perfect because its 4 wire and they are fused together so running it was a dream.

Re: Rookie at Laser, NEED stupid questions answered

Posted: Tue Oct 01, 2013 1:52 am

by rushmore1305

OK so i have not completed the build, the water cooling system, and laser is fully assembled besides the Z bed, i do not know how to set up, i actually created a separate thread on this, maybe someone can direct me on how to do it.

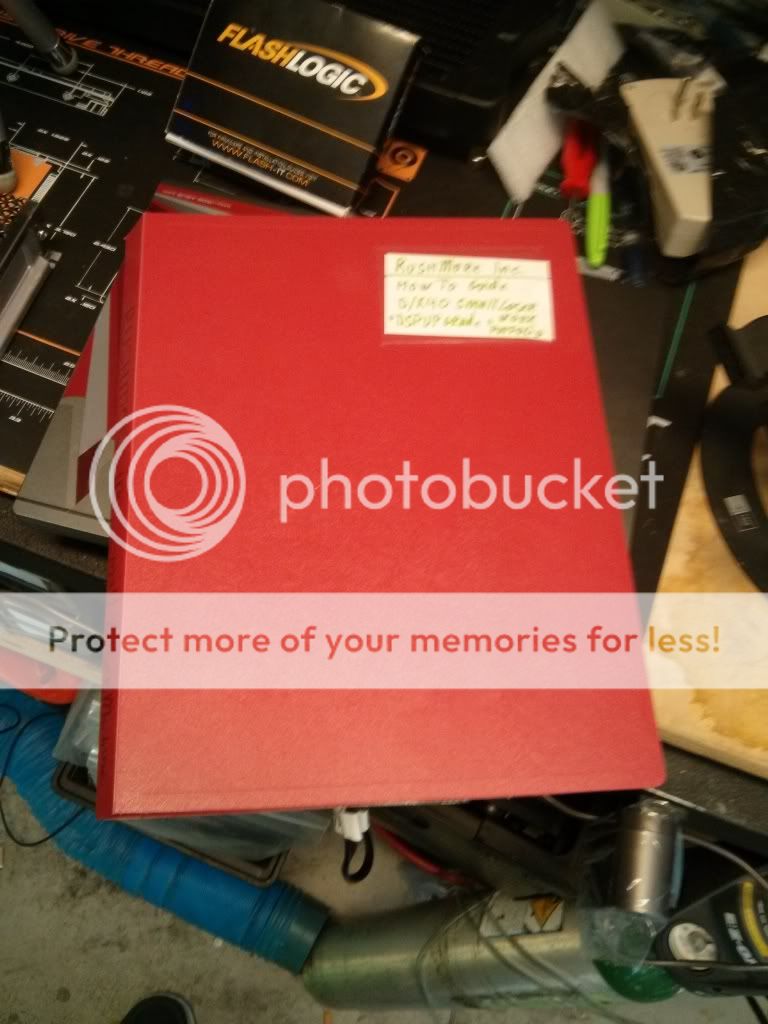

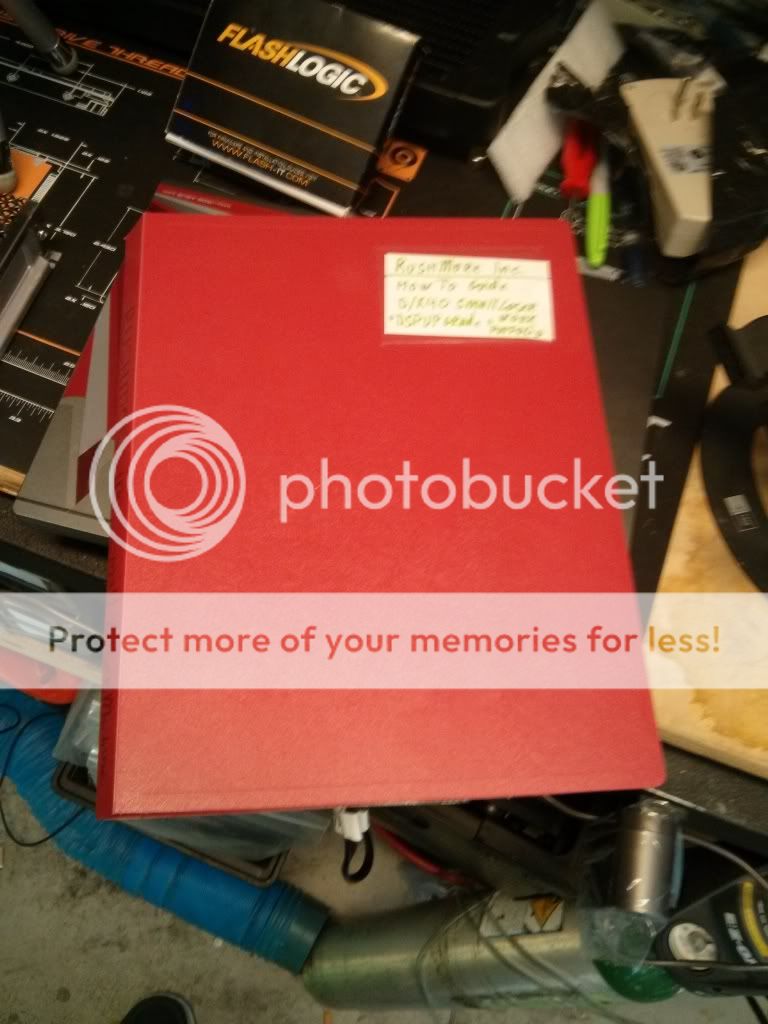

but anyway, please feast your eyes on my take on the DSP.

First i think that everyone should print out themselves the guide that they email you, there are a couple of mistakes in it which i will address in the next post, but for right now, just like previous times i will let the pictures say thousand words.

*********IMPORTANT QUESTION***********

?????????????OHHHHH almost forgot, my laser came with this underneath it, is that bad? will it cause any issues? should i remove it? was it just part of the shipping thing?????????????

ok hopefuilly u guys like what i have done with my laser. the cooling station in the back has the 3 switches in case you are wondering what they are for.

1. Turn on 12v 5amp PSU( Reservoir Light and red cathode behind the switches turn on as an indicator of the PowerON)

2. Toggle power for FANS(radiator(red), Control(green), 2x Exhaust fans(intake and Exhaust, part of the manifold, those are the 3000rpm Scythe FANS, extremely powerful, way better suction then the stock fan)

3. Toggle Lighting inside the WorkArea and Control Area

Re: Rookie at Laser, NEED stupid questions answered

Posted: Tue Oct 01, 2013 10:02 am

by Tech_Marco

OMG!! This is an outstanding job. I never thought about it that a K40 can look that "cool"

It look like that we're in a "car show", in LA

Great job!

Marco

Re: Rookie at Laser, NEED stupid questions answered

Posted: Tue Oct 01, 2013 4:48 pm

by rushmore1305

Tech_Marco wrote:OMG!! This is an outstanding job. I never thought about it that a K40 can look that "cool"

It look like that we're in a "car show", in LA

Great job!

Marco

Thank you for your kind words, that means a lot to me, unfortunatly i am having issues with my set up.

for some reason, when i am following along the guide that you email, i have to draw out the 100x100 box and send it to cut, but when i do, the machine is making some sort of a weird musical almost noise but nothing is moving.

i have now upgraded the OS on the mainboard also to the one you emailed.

have not tried again yet, but not sure.

can you please help, what could be wrong.

both the x and y stepper drivers have to have the RED and Black cable going to 24v psu, correct, because on the diagram there is only one

Re: Rookie at Laser, NEED stupid questions answered

Posted: Wed Oct 02, 2013 10:59 am

by Tech_Marco

Not a problem. It is because the default setting value for "Um" is too far from the correct setting

Ok, let's use some rough value here.

Set the motor driver to 1/8 or 1600. Then set the 'um' to 12.5 or 6.5 (whichever work). It should be able to drive the motor to run quite smooth.

Then, draw a 100mm x 100mm square box.

Enter the Expected value (100mm) and the actual cut value (could be 95 or 45mm something like that).

Use the built-in um calculator on LaserCad to find out the properly um.

Save it then hit "RESET" on LCD to apply for the new setting. Remember, before you can save it, you need to click "READ"

Marco

Re: Rookie at Laser, NEED stupid questions answered

Posted: Thu Oct 03, 2013 2:15 am

by rushmore1305

man this stupid thing is driving me crazy it is not working, no matter what the hell i do, i do not undetstand what is going on, all the wiring is correct, everything is done right

Tech_Marco wrote:Not a problem. It is because the default setting value for "Um" is too far from the correct setting

Ok, let's use some rough value here.

Set the motor driver to 1/8 or 1600. Then set the 'um' to 12.5 or 6.5 (whichever work). It should be able to drive the motor to run quite smooth.

Then, draw a 100mm x 100mm square box.

Enter the Expected value (100mm) and the actual cut value (could be 95 or 45mm something like that).

Use the built-in um calculator on LaserCad to find out the properly um.

Save it then hit "RESET" on LCD to apply for the new setting. Remember, before you can save it, you need to click "READ"

Marco

Re: Rookie at Laser, NEED stupid questions answered

Posted: Thu Oct 03, 2013 3:17 am

by rushmore1305

Tech_Marco wrote:Not a problem. It is because the default setting value for "Um" is too far from the correct setting

Ok, let's use some rough value here.

Set the motor driver to 1/8 or 1600. Then set the 'um' to 12.5 or 6.5 (whichever work). It should be able to drive the motor to run quite smooth.

Then, draw a 100mm x 100mm square box.

Enter the Expected value (100mm) and the actual cut value (could be 95 or 45mm something like that).

Use the built-in um calculator on LaserCad to find out the properly um.

Save it then hit "RESET" on LCD to apply for the new setting. Remember, before you can save it, you need to click "READ"

Marco

the 12 or 6.5 does not work at all, they make a high pitch noise and that is it

Re: Rookie at Laser, NEED stupid questions answered

Posted: Thu Oct 03, 2013 5:01 am

by rushmore1305

when i first turn on the machine, i can hear the motors engage, and when i click the reset button on the control panel i can here the motors whine, but nothing.,

i dont know

how is the wiring suppose to be on the stepper motor,

can someone dierect me, because the wiring diagram that you sent me does not even have power going to one of the stepper motors

and can someone tell me where do the four wires have to go for the Z bed on the control box, and which one of them is power, because there are yellow orange brown and red

Tech_Marco wrote:Not a problem. It is because the default setting value for "Um" is too far from the correct setting

Ok, let's use some rough value here.

Set the motor driver to 1/8 or 1600. Then set the 'um' to 12.5 or 6.5 (whichever work). It should be able to drive the motor to run quite smooth.

Then, draw a 100mm x 100mm square box.

Enter the Expected value (100mm) and the actual cut value (could be 95 or 45mm something like that).

Use the built-in um calculator on LaserCad to find out the properly um.

Save it then hit "RESET" on LCD to apply for the new setting. Remember, before you can save it, you need to click "READ"

Marco

Re: Rookie at Laser, NEED stupid questions answered

Posted: Thu Oct 03, 2013 5:24 am

by rushmore1305

ok all if the guides say something difffernt, can some one please tell me what is the proper pin out from the stepper driver to the motor

in the main guied is says

starting from the far saide, left side

white, blue, yellow red

then in the diagram it goes

yellow white blue red

can someone please tell me the proper way to do this

Re: Rookie at Laser, NEED stupid questions answered

Posted: Thu Oct 03, 2013 7:22 am

by Stephen6309

From your description, the motors may not be wired correctly.

Use a multimeter to find the coil pairs. Connect one pair to A and the other to B on the driver. If the motor runs backwards swap one pair of wires on A or B, but not both.

If you don't have a multimeter, short two wires at a time and see if you can turn the motor. When you can't easily turn the motor those two wires are a pair.

Re: Rookie at Laser, NEED stupid questions answered

Posted: Thu Oct 03, 2013 12:59 pm

by rushmore1305

Stephen6309 wrote:From your description, the motors may not be wired correctly.

Use a multimeter to find the coil pairs. Connect one pair to A and the other to B on the driver. If the motor runs backwards swap one pair of wires on A or B, but not both.

If you don't have a multimeter, short two wires at a time and see if you can turn the motor. When you can't easily turn the motor those two wires are a pair.

i cant get the motor to do anything, besides when the machine turn on the motors sound like they engage, i had it on variotion of wire combination when i moved the motors, via control panel , they felt like they wanted to move but they did not,

Re: Rookie at Laser, NEED stupid questions answered

Posted: Thu Oct 03, 2013 2:12 pm

by Tech_Marco

What you need to do is to unplug the two pairs motor wires and make sure that you have them paired right. On my K40, Red/Blue is a pair and Yellow/White is another pair. That made up A+ A- and B+ B-.

If by mistake you paired A+ with B+(or B-), and A- with B+(or B-), the motor will act very strange. Possible it is the case happening in your setup. The other chance is that the connection on the motor driver got lose. If you got A+ A- connected with B+ B- lose, the motor may move but escaping.

The third possible cause is over-loaded. You have running DC12V 5A power supply and you seems have one DC power supply to power all devices. I don't think it is a good way to do so. Assuming the motors are 1A each so it is 2A total. Then the fan may take 1.25A each so total would be 2.5A. The DSP take about 1A. When added up: 1 + 2.5 +1 = 4.5A. You're driving the DC power supply to the limit and it is truly not a good idea. Plus, you have power Z table and it will take another 1.25A. So, what do we have here?! By the way, how did you power the water pumps and the cooling 3x fans that attached to the water radiator?

That would take another 6~8A !

Instead, you should have DC24V 5A to power the DSP and the motor drivers(and motor), then get a DC12V 5A to power the two fan or other small DC 12V devices.

So, take some careful study on your wiring and re-wire it if possible. Then, get one more power supply or higher current like DC12V 10A if you don't want to get 2nd power supply. I'm pretty sure that UM=12.5 or 6.5 either way will make the motor work, just matter if it is in scale or not.

Marco

Re: Rookie at Laser, NEED stupid questions answered

Posted: Thu Oct 03, 2013 3:27 pm

by rushmore1305

yeah i have pretty much exhausted all those options besides rewiring the whole ordeal

if you look close, i the 24v Power Supply inside the k40(the one you shipped me in the DSP kit), that is power the motors and the laser, controller, then my cooling system is powered by a separate 12v5a psu i bought separate from what i had bought from you, that is driving my dual pumps(for redunducy), fans and lighting)

i do still have the 24v 2.5 amp psu that originaly came with the k40,

do you think i should just wire that independent for the two stepper driivers

but i am going to rewire the whole set up right now, just to make , but i did take it apart and everything seemed to be in order.

Marko can you please link me two motors that i would require if my motors where bad?

i just want to order them in case for some reason they are bad that way i get them before the weekend,

also on the Z bed, how do i wire the 4 wires if i wanted to go straight to the controler?????

i got orange, yellow brown, and some other color.

what was yours like?

Tech_Marco wrote:What you need to do is to unplug the two pairs motor wires and make sure that you have them paired right. On my K40, Red/Blue is a pair and Yellow/White is another pair. That made up A+ A- and B+ B-.

If by mistake you paired A+ with B+(or B-), and A- with B+(or B-), the motor will act very strange. Possible it is the case happening in your setup. The other chance is that the connection on the motor driver got lose. If you got A+ A- connected with B+ B- lose, the motor may move but escaping.

The third possible cause is over-loaded. You have running DC12V 5A power supply and you seems have one DC power supply to power all devices. I don't think it is a good way to do so. Assuming the motors are 1A each so it is 2A total. Then the fan may take 1.25A each so total would be 2.5A. The DSP take about 1A. When added up: 1 + 2.5 +1 = 4.5A. You're driving the DC power supply to the limit and it is truly not a good idea. Plus, you have power Z table and it will take another 1.25A. So, what do we have here?! By the way, how did you power the water pumps and the cooling 3x fans that attached to the water radiator?

That would take another 6~8A !

Instead, you should have DC24V 5A to power the DSP and the motor drivers(and motor), then get a DC12V 5A to power the two fan or other small DC 12V devices.

So, take some careful study on your wiring and re-wire it if possible. Then, get one more power supply or higher current like DC12V 10A if you don't want to get 2nd power supply. I'm pretty sure that UM=12.5 or 6.5 either way will make the motor work, just matter if it is in scale or not.

Marco

Re: Rookie at Laser, NEED stupid questions answered

Posted: Thu Oct 03, 2013 5:30 pm

by Tech_Marco

I can tell you that you will be more happy once you fixed the issue. Being successful the first set things up are great but not the most. Having some 'bumpy road' and you fix the problem one by one is more joyful. Plus, you will be built up a bunch of skill and I'll more happy to give you the graduation hat (We call it square hat

At this time, forget about bad motor or Z table. Focus on the machine is your priority. Usually the motors are good and you better check each wire again. Me sometimes made stupid mistake by making wrong connection on the K40. Looks simple but sometimes a simple thing caused big time!

You don't need to use second power supply for the motors. Just double check the voltage drop on the power supply when the motor is running. If somehow somewhere short circuit happened or not enough current, the voltage will drop dramatically. If something wrong with the motor and if you're driving it by DC24V. When you measure the voltage and found that it is 22V or below, chance is that there is wiring issue! If DC12V drop down to 11V or lower, again something wrong. It could be a faulty power supply. Remember, everything you have done so far are "tools" and you can re-used it. It is what we called "Trouble shooting".

There are two type of DIY folks: Of one type folks are enjoying the most when the project is completed and have a workable product. Another type is that folks enjoying the building process . An excitement won't last long for a completed project so and they moved on to apply modification and enjoy the trouble shooting.

Regardless which type person you're, be patience and enjoy the process. I tell you a story: without too much help from other and no manual, it took me 6 months to learn how to use OrCad PCB program by using the tactic of "Try and error". The Orcard got bunch of parameters and keys. Everyday after work, I spent about 2hrs to test each parameter. After six months testing I got a combination worked out and since then, I could do schematic, parts list, and PCB all in one. SIX months wasn't short right? How long did you spend on your project, two weeks? So, no complain solider, move on!

Marco