Page 2 of 4

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Posted: Tue Feb 26, 2013 1:06 pm

by dubstar_04

1n2 wrote:dubstar_04 wrote:

I really wanted to be able to cut wood using the machine but as yet i can't cut any type of wood without it burning.

Anyone else had any luck?

EDIT: After a google search i have ordered some 3mm birch ply as this seems to be the wood of choice for laser cutting.

Hi Dubstar

Today I have spent 5 hours experimenting with settings and materials.....should have been working but hey ho.

I cut 3mm birch ply beautifully just a little browning of the edge.

After much testing I used speed 13 and power 41% perfect cut no burning!

Just out of curiosity which way up have you got your lens ? I cut and engrave MUCH cleaner with the curve down.

Hope this helps

John

Hi John,

The lense is curve down, this is how the machine came. I am wondering if the lightobject lense will improve the machine?

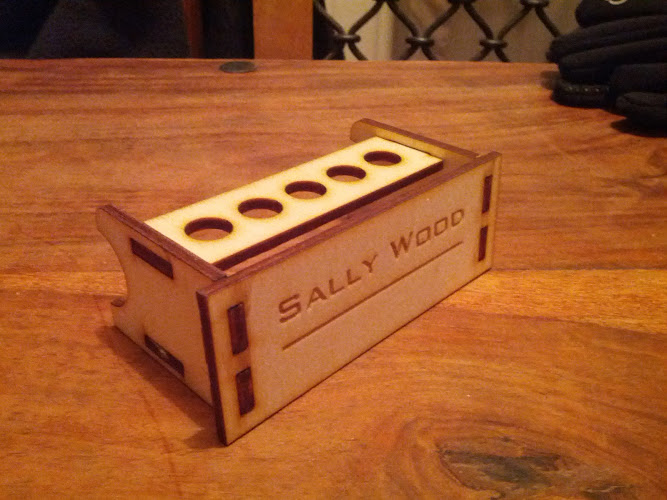

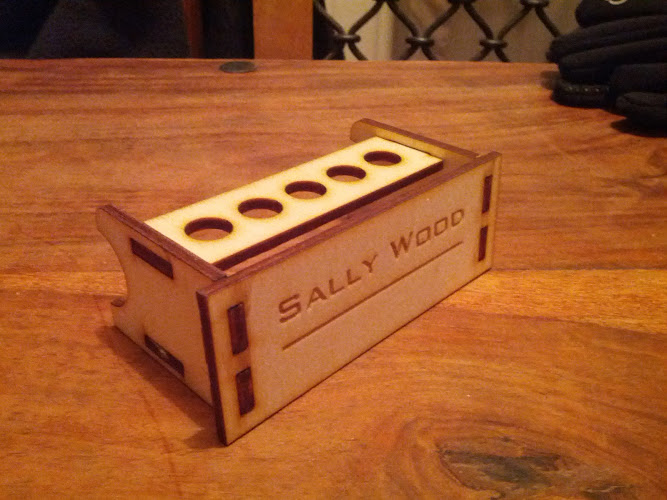

My birch ply came today and i had a quick go with it by making a little pen holder.

Here are some pictures:

The cuts were ok but i had the power too high or the speed too low as it has burnt the under side where the beam hits the steel.

I need to spend some time testing the settings and understanding the PPI feature of the DSP. I have also ordered some 6mm birch ply to see if the machine will cut through that.

Thanks,

Dan

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Posted: Wed Feb 27, 2013 1:08 pm

by 1n2

Hi Dan

Love the invite ......is the pen holder your design?...very neat.!

What else ya burning into shape?

Have popped up a couple of pictures of just some cutout I made (basically testing and playing)

- this is the cut from the top.the pentangle is 1" dia

- cutout-top.jpg (41.55 KiB) Viewed 5709 times

When using mesh for the tables I think I must be getting reflected heat which was burning the wood even with my home brew air assist. (a nice one from Marco is next up)

- same cut but from underneath ..next to no burning....

- cutout-bottom.jpg (37.78 KiB) Viewed 5709 times

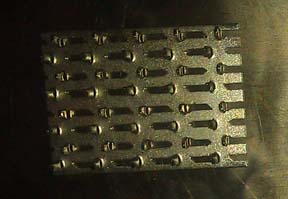

I bought some of these from B & Q its halved the "burning marks"

- rest02.jpg (32.01 KiB) Viewed 5709 times

- I think they are used for joining timber

- rest01.jpg (29.54 KiB) Viewed 5709 times

Maybe we should have a topic for us all to post our work ?

I have made a couple of front panels from sprayed perspex ( I am quite pleased with the results)

John

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Posted: Wed Feb 27, 2013 3:18 pm

by Tech_Marco

1n2 wrote:Hi Dan

Maybe we should have a topic for us all to post our work ?

I have made a couple of front panels from sprayed perspex ( I am quite pleased with the results)

John

If you guys want a place to post art work, sure I can create a new topic to handle it. Let me know the best name you guys perfer to

Marco

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Posted: Wed Feb 27, 2013 9:45 pm

by wctx1977

I like the idea of a new topic for artwork made with this machines. I think that would help us to develop more creativity learning from others.

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Posted: Sun Mar 03, 2013 10:19 am

by dubstar_04

More laser upgrades:

I made a panel for the dsp control today. I am going to make one from acrylic eventually but i had some ply handy so i make a test cut.

It fitted perfectly, first time.

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Posted: Sun Mar 03, 2013 10:31 am

by dubstar_04

I have been having problems with the machine producing some misaligned cuts:

Is it skipping steps?

Anyone know how to solve this?

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Posted: Mon Mar 04, 2013 1:43 am

by waltfl

Hi

it looks like it comes from your drawing. the picture is not the best to see.

greetings

waltfl

dubstar_04 wrote:I have been having problems with the machine producing some misaligned cuts:

Is it skipping steps?

Anyone know how to solve this?

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Posted: Mon Mar 04, 2013 2:35 am

by dubstar_04

waltfl wrote:Hi

it looks like it comes from your drawing. the picture is not the best to see.

greetings

waltfl

dubstar_04 wrote:I have been having problems with the machine producing some misaligned cuts:

Is it skipping steps?

Anyone know how to solve this?

I have attached the file, i can't open it at the moment.

Some of the cut shifted to the right after the engraving. Maybe i should try again?

Thanks,

Dan

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Posted: Mon Mar 04, 2013 10:16 am

by dubstar_04

dubstar_04 wrote:waltfl wrote:Hi

it looks like it comes from your drawing. the picture is not the best to see.

greetings

waltfl

dubstar_04 wrote:I have been having problems with the machine producing some misaligned cuts:

Is it skipping steps?

Anyone know how to solve this?

I have attached the file, i can't open it at the moment.

Some of the cut shifted to the right after the engraving. Maybe i should try again?

Thanks,

Dan

I have checked the file and the cut is aligned.

What could caused misaligned cuts?

Slipped teeth, missed steps?

Any help appreciated.

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Posted: Mon Mar 04, 2013 12:28 pm

by 1n2

Hi Dan

I had exactly this effect

Was there any juddering before it displaced? (it has only shifted a small amount so it would not be much of a judder).

If so check the X Y home connections and switches for loose connections

download and run the file a few times using card does it repeat at exactly the same point (double check this by changing the speed)

If it is in the same spot I would look very closely at the drawing.

I will see if it run here but it will have to be tomorrow

John

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Posted: Mon Mar 04, 2013 2:16 pm

by waltfl

Hi there

ok do the following:

reset with the display botton

reset in lasercut with " datum"

format the machine memory with the dispaly menue option

format from lasercut during download.

let me know

greetings

waltfl

quote="dubstar_04"]

dubstar_04 wrote:waltfl wrote:Hi

it looks like it comes from your drawing. the picture is not the best to see.

greetings

waltfl

dubstar_04 wrote:I have been having problems with the machine producing some misaligned cuts:

Is it skipping steps?

Anyone know how to solve this?

I have attached the file, i can't open it at the moment.

Some of the cut shifted to the right after the engraving. Maybe i should try again?

Thanks,

Dan

I have checked the file and the cut is aligned.

What could caused misaligned cuts?

Slipped teeth, missed steps?

Any help appreciated.[/quote]

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Posted: Thu Mar 07, 2013 12:13 pm

by 1n2

Hi Dan

I tried to run the file for the kindle rest.

It loaded in portrait with the hinge bit at the bottom.

I downloaded it to the laser (knowing it would probably be too big for the cutting bed that way up) adjusted the power settings to cut on card (incidentally I see your setting are set VERY high for ply wood is your beam lined up?).

When it started it began at the top (ie the home position) with the hinge bit so it has inverted from that on the screen.

I tried rotating it 90 degrees this time it started not only upside down but not rotated??? I cleared my memory and restarted the pc but it stayed the same.

Did you make the drawing or is it one that was available somewhere?

Do you have a CDR of it for me to try?

John

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Posted: Sat Mar 16, 2013 6:13 am

by dubstar_04

1n2 wrote:Hi Dan

I tried to run the file for the kindle rest.

It loaded in portrait with the hinge bit at the bottom.

I downloaded it to the laser (knowing it would probably be too big for the cutting bed that way up) adjusted the power settings to cut on card (incidentally I see your setting are set VERY high for ply wood is your beam lined up?).

When it started it began at the top (ie the home position) with the hinge bit so it has inverted from that on the screen.

I tried rotating it 90 degrees this time it started not only upside down but not rotated??? I cleared my memory and restarted the pc but it stayed the same.

Did you make the drawing or is it one that was available somewhere?

Do you have a CDR of it for me to try?

John

I havent been able to use the laser for a while as i have been busy on other projects.

I have done some testing with power setting with you saying that 75% is high.

Well my machine only just cuts through 3mm birch Ply at 75%, in some places it doesnt fully cut through.

If i want to be sure that the piece if fully cut i have to use 90% power.

When using PPI it only uses 8 Amps, regardless of the power setting, without PPI it is about 17 Amps at 100% power is this correct?

I am still trying to track down the problem of missaligned cuts also.

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Posted: Sat Mar 16, 2013 6:58 am

by 1n2

dubstar_04 wrote:1n2 wrote:Hi Dan

I tried to run the file for the kindle rest.

It loaded in portrait with the hinge bit at the bottom.

I downloaded it to the laser (knowing it would probably be too big for the cutting bed that way up) adjusted the power settings to cut on card (incidentally I see your setting are set VERY high for ply wood is your beam lined up?).

When it started it began at the top (ie the home position) with the hinge bit so it has inverted from that on the screen.

I tried rotating it 90 degrees this time it started not only upside down but not rotated??? I cleared my memory and restarted the pc but it stayed the same.

Did you make the drawing or is it one that was available somewhere?

Do you have a CDR of it for me to try?

John

I havent been able to use the laser for a while as i have been busy on other projects.

I have done some testing with power setting with you saying that 75% is high.

Well my machine only just cuts through 3mm birch Ply at 75%, in some places it doesnt fully cut through.

If i want to be sure that the piece if fully cut i have to use 90% power.

When using PPI it only uses 8 Amps, regardless of the power setting, without PPI it is about 17 Amps at 100% power is this correct?

I am still trying to track down the problem of missaligned cuts also.

Hi Dan

Regarding power if the lens is not dirty then

My guess would be either your alignment is bad or the work piece is out of focus I cut 6mm acrylic easily with 50% power setting at a speed of 3 (agreed this is with air assist.)

I posted some boxes I had made with 3mm birch ply. these were cut at a speed of 13 and power set to 41.

18Mamps seems to be the max (100%)for a 40 watt tube according to the guff I have read. (that is if I understood what I read correctly)

and further it seems that 100% in the Lasercad software does not equal 100% (18Ma) on the laser 18Ma seems to be achieved way before 100%

now the miss-alignment.Is it happening with ALL your drawings?

I hope I am not teaching grandma to suck eggs...this is how I would go about it (and did so to find two faults.....1 caused by me, loose connection, and 1was a bad microswitch)

By a process of elimination we should be able to sort it.

If its happening consistently with everything I would say to look at settings.

If it happens randomly ie in a different place each time with the same drawings I would look for a loose connection.

If its happening with just that drawing (or all drawings from the same source) I would look to the drawing.

My method would be make a very basic drawing (using Lasercad thereby eliminating corel draw from the equation) that engraves a shape then cuts the engraving out. By keeping it simple to start we should be able add tests one thing at a time.(sorry if this is obvious but sometimes when ya too close to the elephant all you see is grey)

John

PS did you draw the kindle rest or get the file elsewhere?..

Re: Dubstar_04 - 40w Chinese Laser DSP Conversion

Posted: Sun Mar 17, 2013 3:58 am

by dubstar_04

1n2 wrote:

Hi Dan

Regarding power if the lens is not dirty then

My guess would be either your alignment is bad or the work piece is out of focus I cut 6mm acrylic easily with 50% power setting at a speed of 3 (agreed this is with air assist.)

I posted some boxes I had made with 3mm birch ply. these were cut at a speed of 13 and power set to 41.

18Mamps seems to be the max (100%)for a 40 watt tube according to the guff I have read. (that is if I understood what I read correctly)

and further it seems that 100% in the Lasercad software does not equal 100% (18Ma) on the laser 18Ma seems to be achieved way before 100%

now the miss-alignment.Is it happening with ALL your drawings?

I hope I am not teaching grandma to suck eggs...this is how I would go about it (and did so to find two faults.....1 caused by me, loose connection, and 1was a bad microswitch)

By a process of elimination we should be able to sort it.

If its happening consistently with everything I would say to look at settings.

If it happens randomly ie in a different place each time with the same drawings I would look for a loose connection.

If its happening with just that drawing (or all drawings from the same source) I would look to the drawing.

My method would be make a very basic drawing (using Lasercad thereby eliminating corel draw from the equation) that engraves a shape then cuts the engraving out. By keeping it simple to start we should be able add tests one thing at a time.(sorry if this is obvious but sometimes when ya too close to the elephant all you see is grey)

John

PS did you draw the kindle rest or get the file elsewhere?..

Hi john

i found kindle stand on thingiverse, it was meant to be a phone holder, but i scaled it accordingly.

I am making a little progress.

Power:

It seems to be a problem with using the PPI feature. i.e If PPI is selected the machine cannot fully cut 3mm Birch ply with a power setting < 75%

Without PPI, 10mm/s and 25% power gets a clean cut.

Alignment:

It seems that the problem is caused by engraving.

if i cut an object that has no engraving it works fine,however ifi cut the same object with engraving it all becomes missaligned.

I can reproduce this consistantly.

I am really dissapointed with this issue as i bought a DSP specifically for this task rather than a cheaper alternative from a Laos board or chris's circuits, so i hope to get it resolved.

i will upload some photos of the attached file being cut to show the missalignment on a number of attempts.

thanks,

Dan