So now that i have everything working on the hardware side, i think i should post some pictures in this original post, that way people who are new to this like i was can get an idea what this thread will entail and such, and others who either seen this or who are knowledgable can see right away if they can take any info out of this or not.

***NOTICE*** just a couple of month ago i did not know a single thing about lasers or anything related, I have come a long way, huge thanks to the community and especially Marco, LIGHTOBJECT by far best Customer Service EVER!!!

So this thread is BY NEWBIE, FOR NEWBIES/ROOKIES ****NOTICE****

In this update i will just post some pictures of completed unit, in a couple of days i will post specs and what i think anyone who is just getting into this should know about their parts and other simple but very important things that i have made mistakes on or simply overlooked.

Soon: next to each topic will have a link to the portion of the thread where it goes into detail about specified.

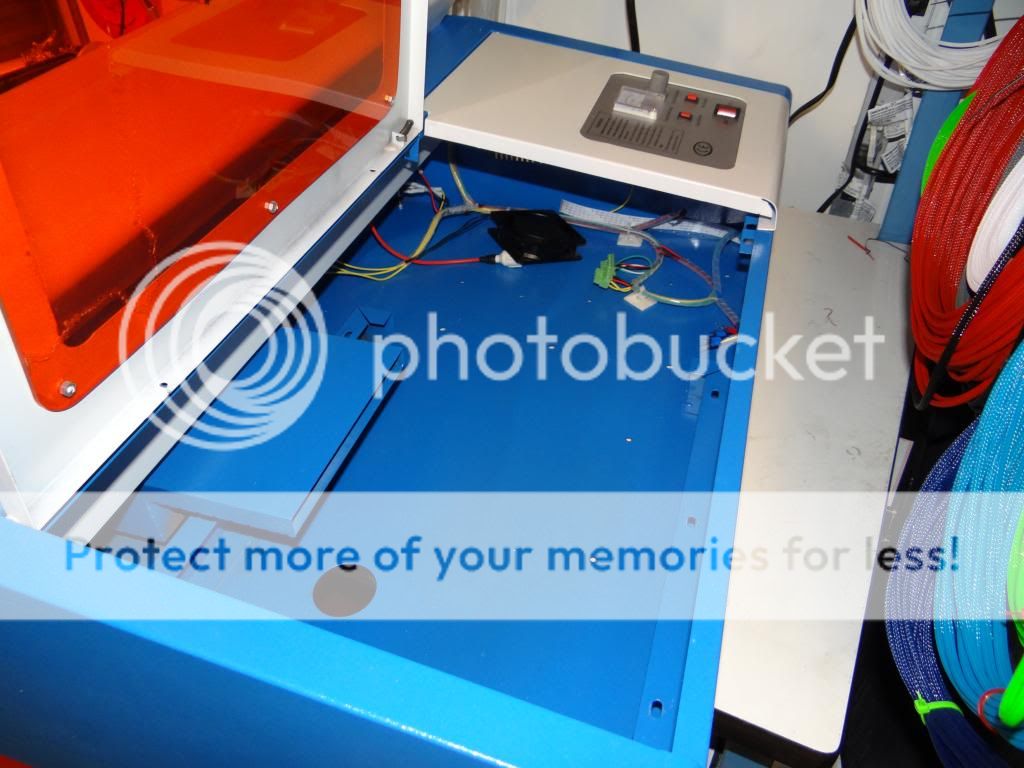

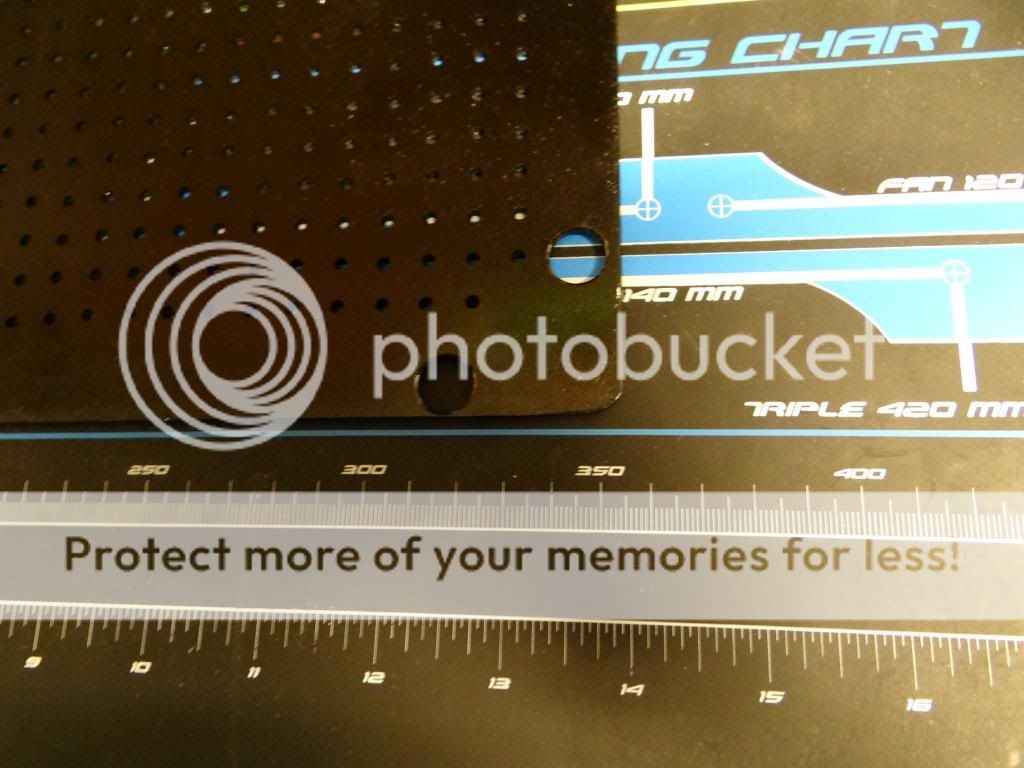

Assembled UNIT(Functional but , 90% cosmetic)

COOLING SYSTEM:

LIGHTING + Modifications

WIRING

OP

hello everyone, i just recently decided to get into the laser cutting bussienss

what i need to do is to cut patterns in acrylic/plexiglass that are 2-3mm thick.

so i have purchased the k40 laser from ebay for 700 and the DSP kit from light object. i am hoping that it will be enough to get me started.

i have a lot of experience with solidworks and hoping that i can either transfer the files into the type that DSP will recognize, if not ill probobly be able to learn the software fairly easy, i cant imagine the terminology being much differnt.

so as i have recieved all the parts i am just creating this thread to hopefully recieve some guidens and critisims on my progress.

but as i am looking into this i have my first couple of questions.

1. What should the liquid temperature be that is entering the Laser Tube.

2. do u guys think this 40watt laser be able to cut plexi that is 3mm thick.

3. do u guys have any advice or anything i should do right away first or second or what not.

please i highly welcome any advice, as i am a total newb at this and really require some help.

i will be posting pictures of everything first thing in the morning.

please help me resolve these ongoing issues so i can come up with more!

P.s i was also wondering if i should have bought something else to go along with the DSP kit that they sell on lightobjects site.